clay county histories

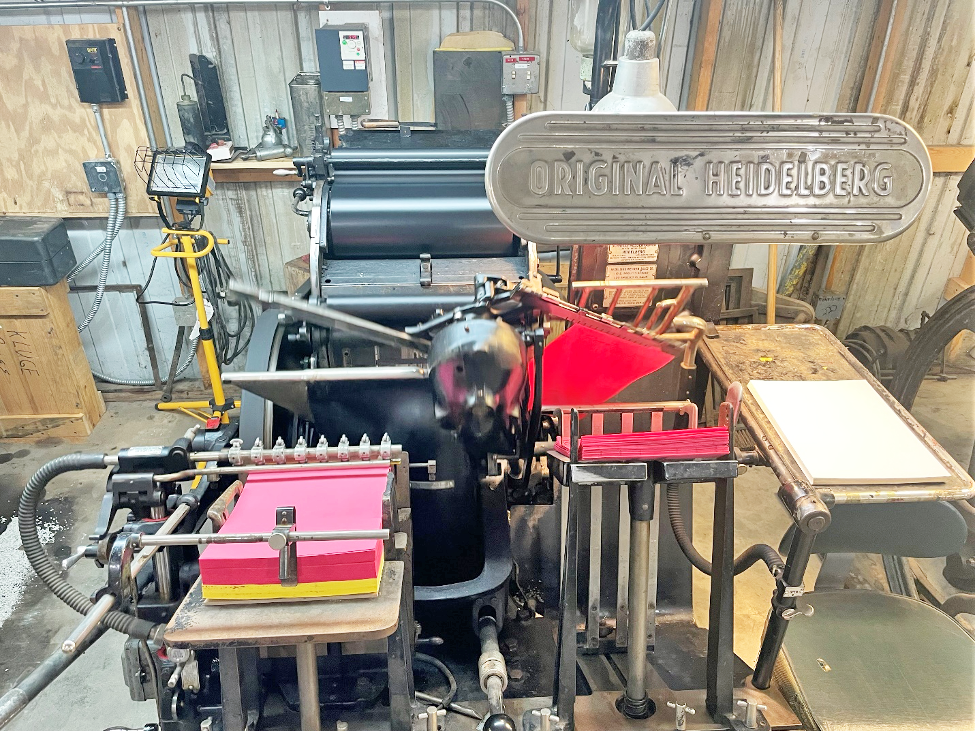

The Original Heidelberg at WMSTR

Markus Krueger | Program Director HCSCC

Every Labor Day weekend, about 20,000 people a day from all over the country gather at Rollag for the Western Minnesota Steam Threshers Reunion. Since 1954, WMSTR volunteers keep in working order a village worth of historic buildings, giant sheds worth of old engines, blacksmith shops, sawmills, a 1920s carousel, an actual train, and old farm machinery farther than the eye can see. It is likely the largest such gathering in the world.

Five years ago, I started volunteering at WMSTR’s Pioneer Press print shop. This big building has everything you need to be a mid-1900s print shop: Drawers of movable type, linotype machines that cast words in hot lead, a contraption the size of my bedroom that folds newspapers, and my favorite, the letterpresses. I can’t describe how cool these things are. A spin of a wheel sets a thousand pounds of cast iron in motion like a Sherman tank dancing ballet. Letterpresses like this used to be in every town in America, printing bulletins, labels, fliers – any sheet of paper with words or images.

In the mid-1960s, the printing industry changed radically, rendering this old equipment obsolete. While thousands of these machines were sold for scrap, thousands more were saved because, just like an old Chevy or Harley, those who used these presses loved them. In 1972, Bob Brecken of the Hawley Herald moved some of his beloved out-of-date printing equipment to Rollag. Other printers and sons-of-printers added machines from Ada, Browns Valley, Pelican Rapids, Barnesville, and elsewhere. Half a century later, retired printers are teaching younger generations of WMSTR volunteers how to operate and fix these machines while visitors watch.

I’ve been trained in on a few different machines over the years by teachers like Jerome Ekre and John Schaffer. This year I learned how to operate “the prince of presses,” a beautiful piece of century-old German engineering called the Original Heidelberg. My teacher was the very impressive Al Frisinger, who spent 30 years mastering seemingly every aspect of printing machinery and technology before he retired. Al took this particular machine out of the Hawley Herald to install at Rollag. He taught me how to work it: lift the big lever and give it a twist, turn the little lever on top, press the button by my left knee and quickly pull the big knob. And then, behold.

A vacuum arm hovers over the stack of blank paper and sucks up a single page. That page is quickly snatched by one of the two grabber arms that twirl around and give the machine its nickname: the Windmill. The grabber brings the paper to just the right spot to be squished against the metal type (which is inked up by rollers between squishes). After the paper kisses the inked letters, the grabber arm moves it 90 degrees more and a puff of air blows the printed flier onto the stack of finished products. Meanwhile, simultaneously, the other grabber snatches a fresh sheet of paper from the vacuum arm on its way to be squished against freshly-inked type, and so on.

You can’t surf the internet on it, but the Original Heidelberg is way cooler than my smart phone. Thanks to everyone at WMSTR for keeping your machines running!